The Bambu Lab H2C is a professional-grade multi-material 3D Printer built for precision, efficiency, and production reliability. With true 7-color printing, purge-saving technology, a high-torque PMSM servo extruder, and AI-powered monitoring, it delivers flawless, ready-to-use parts straight from the printer. Designed to handle engineering materials with a heated chamber, 350 °C hotends, and advanced filtration, the H2C empowers creators and manufacturers to print complex, functional designs in one seamless workflow.

Redefine what’s possible with advanced multi-material and multi-color printing. The Bambu Lab H2C is engineered for creators and professionals who demand precision, efficiency, and production-grade reliability all in one powerful system.

Print complex, full-color models straight from the build plate. With support for six colors plus a dedicated seventh nozzle, the H2C eliminates painting and post-assembly, turning digital designs into finished parts effortlessly.

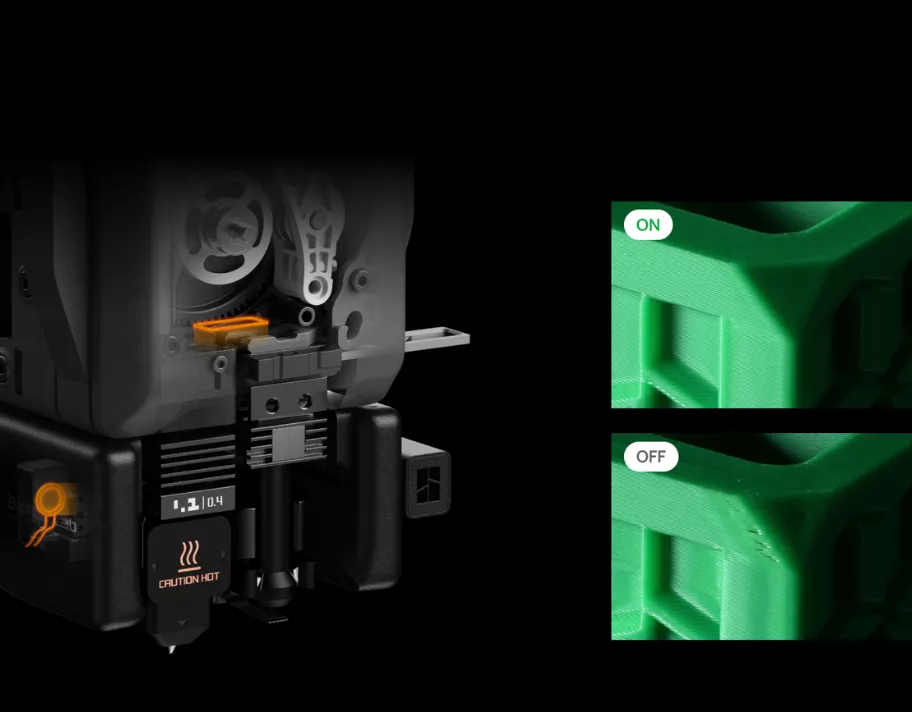

Advanced purge-saving algorithms significantly reduce filament waste and print time. Get vibrant, detailed multi-color prints with cleaner transitions and far greater material efficiency.

Combine rigid, flexible, and engineering materials within a single print. From TPU joints to fiber-reinforced structures, the H2C enables functional, assembled-ready parts without manual intervention.

The intelligent Vortek system enables fully automatic filament and hotend switching with minimal purge waste. Dedicated hotends ensure consistent performance across different materials while maximizing uptime.

Designed for continuous operation, the H2C delivers exceptional surface quality, sharp edges, and reliable consistency making it ideal for professional production and demanding workflows.

A high-torque PMSM servo motor delivers up to 10 kg of extrusion force while monitoring extrusion behavior at 20 kHz. This ensures stable high-speed printing with real-time clog and filament error detection.

Vision encoder calibration enables motion accuracy below 50 microns. Automatic drift compensation ensures consistent precision and repeatable print quality over long-term use.

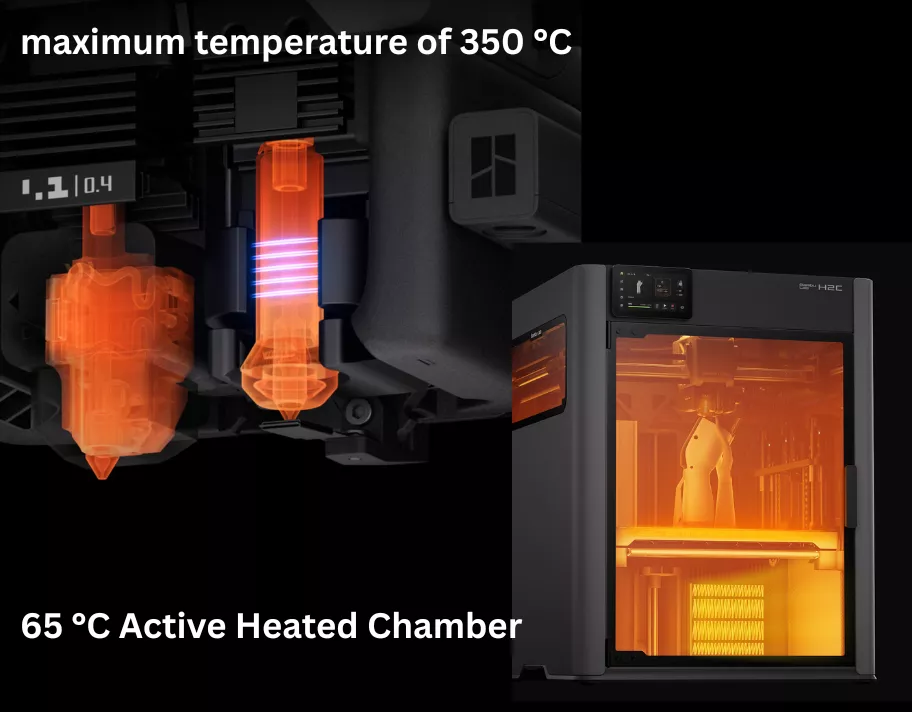

All seven hotends reach temperatures up to 350 °C, supported by a 65 °C actively heated chamber. This combination minimizes warping and maximizes layer adhesion for high-performance engineering filaments.

A professional three-stage filtration system—G3 pre-filter, H12 HEPA, and activated carbon captures harmful particles and odors, keeping your workspace clean and safe.

With 59 sensors and a quad-camera vision system, the H2C continuously analyzes print performance in real time, instantly detecting errors and ensuring reliable results without constant supervision.

An AI-driven nozzle camera monitors extrusion behavior, while automated pre-flight inspections verify build surface cleanliness and print settings before every job.

The fully enclosed, flame-retardant chamber and closed-loop temperature control provide dependable thermal stability and enhanced safety during long print sessions.

Printing Technology

Fused Deposition Modeling

Body

Build Volume (W*D*H):

Single Nozzle (Left): 325*320*320 mm³

Single Nozzle (Right): 305*320*325 mm³

Dual Nozzle: 300*320*325 mm³

Total Volume (Two Nozzles): 330*320*325 mm³

Chassis: Aluminum and Steel

Outer Frame: Plastic and Glass

Physical Dimensions

Machine Size: 492*514*626 mm³

Net Weight: 32.5 kg

Working Temperature

10 °C – 30 °C

Heatbed

Build Plate Material: Flexible Steel Plate

Included Build Plate: Textured PEI Plate

Supported Build Plates: Textured PEI, Engineering Plate

Max Heatbed Temperature: 120 °C

Chamber Temperature Control

Active Chamber Heating: Supported

Max Chamber Temperature: 65 °C

Toolhead

Extruder Gear: Hardened Steel

Nozzle: Hardened Steel

Max Nozzle Temperature: 350 °C

Supported Nozzle Diameter: 0.2 / 0.4 / 0.6 / 0.8 mm

Filament Cutter: Built-in

Filament Diameter: 1.75 mm

Extruder Motor: Bambu Lab High-precision PMSM

Speed

Max Toolhead Speed: 1000 mm/s

Max Toolhead Acceleration: 20,000 mm/s²

Max Hotend Flow: 40 mm³/s

(*Tested with 250 mm round model, Bambu Lab ABS, 280 °C)

Air Purification

Pre-filter Grade: G3

HEPA Filter Grade: H12

Activated Carbon: Granulated Coconut Shell

VOC Filtration: Superior

Particulate Matter Filtration: Supported

Software

Slicer: Bambu Studio; supports third-party slicers (SuperSlicer, PrusaSlicer, Cura*)

OS Support: macOS, Windows, Linux

Cooling

Part Cooling Fan: Closed Loop Control

Hotend Cooling Fan: Closed Loop Control

Main Control Board Fan: Closed Loop Control

Chamber Exhaust Fan: Closed Loop Control

Chamber Heat Circulation Fan: Closed Loop Control

Auxiliary Part Cooling Fan: Closed Loop Control

Toolhead Enhanced Cooling Fan: Closed Loop Control

Electronics & Control

Touchscreen: 5" 720*1280

Storage: 8 GB eMMC + USB Port

Interfaces: Touchscreen, Mobile App, PC App

Motion Controller: Dual-core Cortex-M4 + Single-core M7

Application Processor: Quad-core ARM with NPU

Electrical Requirements

Voltage: 100-120 VAC / 200-240 VAC, 50/60 Hz

Max Power*: 1800 W @ 220 V / 1250 W @ 110 V

Typical Power (PLA): 200 W @ 220 V / 200 W @ 110 V

Supported Filament Types

PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS;

Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA, PPA, PPS

Sensors & Recovery

Live View Camera: Built-in, 1920*1080

Nozzle Camera: Built-in, 1920*1080

BirdsEye Camera: Built-in, 3264*2448 (Laser Edition)

Toolhead Camera: Built-in, 1600*1200

Door Sensor: Supported

Filament Run Out Sensor: Supported

Filament Tangle Sensor: Supported

Filament Odometry: Supported with AMS

Power Loss Recovery: Supported

Network Control & Wi‑Fi

Ethernet: Not Available

Wireless Network: Wi‑Fi

Network Kill Switch: Not Available

Removable Network Module: Not Available

802.1X Access Control: Not Available

Wi‑Fi Frequency: 2.4 GHz & 5 GHz bands

Wi‑Fi Protocol: IEEE 802.11 a/b/g/n